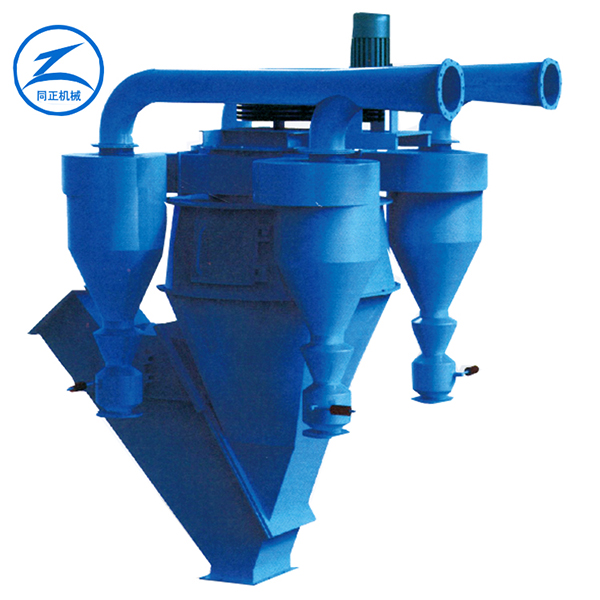

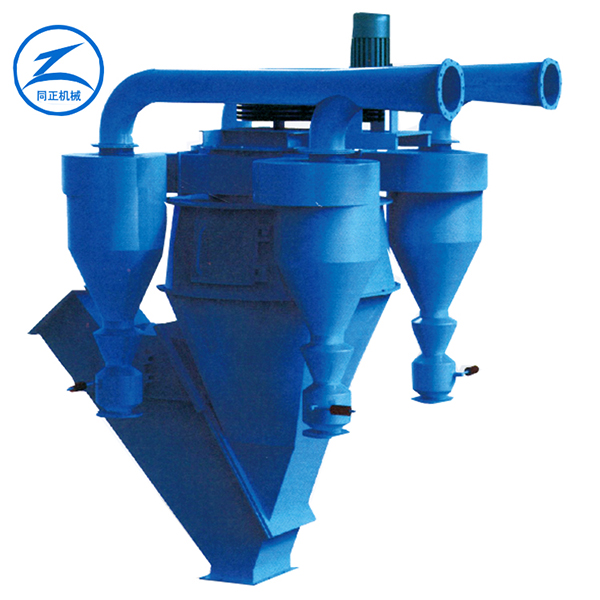

TZ-SF Series Artificial Sandstone Pneumatic Separation Fines Removal Device

As domestic natural sand has been unable to meet the needs of the rapidly growing construction industry . The demand for artificial sand has increased rapidly. Jiangsu Tongzheng Machinery Manufacturing Co., Ltd. in the company owned by the national invention patent products TS series three separation powder machine based on the V type selection and combination of powder machine, made of TZ-SF composite artificial sand powder and windowing machine. The product can be divided into four kinds of sand and powder of different thickness, which conform to the market demand and have been accepted by users. The product has been listed as the Ministry of science and technology Chinese “ artificial sand winnowing powder removing machine industry innovation project”.

TZ-SF Series Artificial Sandstone Pneumatic Separation Fines Removal Device Description

This product has been applied to Wuhan Xinjinyu Building Material Environment Protection Co., Ltd project, Guizhou Zhongyi Building Labor Co., Ltd project special artificial sand production.

Main Features:

- Adavnced separation principle : multi-stage separation system, material flow field is optimized with aerodynamics analysis method based on characteristics of sand to reduce running resistance significantly, achieve high separation and energy efficiency , and is superior pver traditional water washing separation process

- The V-shaped breaking and grading area has a simple structure and less consumables; there is no electric breaking device, the pressure difference loss is small, the operation is stable, and the power consumption is low;

- High classification accuracy: The de-powdering machine adopts the national patented “eddy current rectifier”. The airflow in the rectifier only rises but does not rotate relative to the rotor. The material is repeatedly cleaned in the sorting area, and the classification accuracy is high.

- Simple operation:

- The cage rotor adopts variable frequency stepless speed regulation. It has a large adjustment range, is easy to adjust, and is sensitive and reliable.

- High classification efficiency: “V”-shaped powder separation area is equipped with multiple layers of separation and classification plates, which are repeatedly broken up and blown away, so that the discharged coarse powder has almost no fine powder. There is airflow at the discharge port in the sedimentation classification area to blow away the fine powder in the medium material again, and the fine powder content in the medium material is also greatly reduced. The cage rotor classification area has added guide plates, and the classification is more accurate and effective.

- The wear-resistant parts have low maintenance workload and long service life; the main parts of the powder removal machine are made of imported wear-resistant steel plates, which effectively increases the service life. The whole machine has been dynamically balanced and runs smoothly in the full speed range.

- The main shaft lower bearing seal adopts a new design, which effectively solves the two major problems of dust ingress and lubricating oil leakage in the bearing, and effectively prolongs the service life of the bearing.

- When designing the powder remover foundation, the principle of mechanical vibration reduction was adopted, so that the vibration frequency of the powder selector foundation does not form an integer multiple relationship with the natural frequency of the selector, fundamentally ending the long-standing resonance problem of the selector.

- The coarse sand pipe, medium coarse sand pipe and fine sand pipe all adopt double interlocking air valves, which greatly reduces the system air leakage rate and overcomes the defect of large dust during the operation of the previous powder removal machine.

- The system uses double interlock air valves and internal circulating air to effectively reduce system air leakage and reduce dust emission pollution during operation.